Marka loo eego horumarinta warshadaha mishiinada, wax soo saarka mishiinada oo aad u badan ayaa u baahan in la farsameeyo. Caadi ahaan, alaabta mashiinada la dhammeeyey waxaa lagu farsameeyaa jarida, shiididda iyo nadiifinta.

Waxaa jira xaqiiqo ah in tayada taayirrada abrasive ee suuqa ay aad uga duwan yihiin.Cabashada ugu weyn ee tayada ayaa ah "dareenka gaaban ee giraangiraha xajinta", "Furnaanta hoose ee taayirrada xajinta", iyo "shilku wuxuu dhacay inta lagu jiro isticmaalka".

Markaa si sax ah u dooro taayirrada xajinta waa mid aad muhiim u ah.

Waxaa jira talooyin qaar in la wadaago sida hoos ku qoran

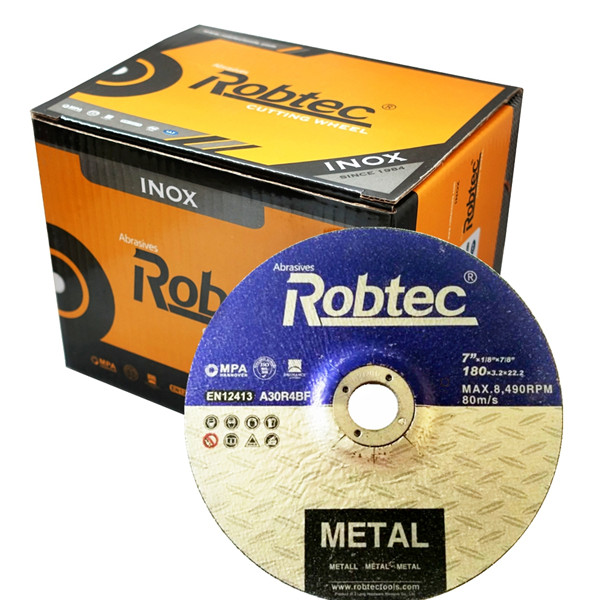

1. Si sax ah u dooro astaanta.

Waxaa jira dhowr kun oo warshadood oo loogu talagalay taayirada abrasive ee Shiinaha, oo leh tayo iyo qiimo kala duwan.Warshad weyn (sida J LONG) had iyo jeer waxay dammaanad qaadi kartaa tayada ma aha oo kaliya sababtoo ah nidaamka xakamaynta tayada adag, laakiin sidoo kale waxay leeyihiin adeeg iibka ka dib. .Iyo sidoo kale waxay awood u leeyihiin inay ka dhigaan badeecada ku habboon shuruudahaaga gaarka ah.

2. Dooro taayirrada xajinta saxda ah sida ay yihiin walxaha aad farsamayn doonto.

Tusaale ahaan, marka maaddadu ay aad u adag tahay ama ay leedahay aag ballaaran oo lagu shaqeynayo, saxanka fiiqan ayaa ka fiican doorashada;Marka maaddadu ay jilicsan tahay ama aaggu yar yahay, saxanka waara ayaa door fiican leh.

3. Dooro taayirrada xaaqaya hadba mashiinka aad isticmaalayso

Marka awoodda mishiinka goyntu ay weyn tahay, taayirrada abrasive ee joogtada ah ee leh xawaarahooda shaqo sare ayaa ah doorashada ugu fiican.Marka mashiinka goynta uu leeyahay awood hoose, saxan khafiif ah oo fiiqan ayaa ka sii fiican.

RPM mashiinku waa inuusan dhaafin RPM ku calaamadsan saxanka.

4. Dooro taayirrada xajinaya sida ay yihiin walxaha la farsamaynayo.

Waxaa jira dhowr abrasives oo loogu talagalay walxo kala duwan oo lagu farsameeyo, sida Brown Fused Aluminum, White Fused Aluminum, Silicon carbide iyo wixii la mid ah.

Aluminiumka isku qasan ee bunni ah ayaa inta badan loogu talagalay dhammaan noocyada birta birta ah;Aluminiumka isku dhafan ee cad cad waxaa inta badan loogu talagalay birta aan lahayn;Silicon carbide inta badan waxaa loogu talagalay granite, dhagaxa, birta birta ah iyo wixii la mid ah.Caadi ahaan waxaad ka heli kartaa shayga, codsiga, RPM calaamadda taayirrada xoqan.

Hal kelmad, badbaadadu waa shuruudaha aasaasiga ah ee taayirrada abrasive.Taayirrada abrasive tayada wanaagsan waa inay lahaadaan dheelitirnaan qumman oo ku saabsan adkeysiga iyo fiiqan, ma guban walxaha la warshadeeyay, oo leh waxqabad wanaagsan dhammaan noocyada alaabada.

Waqtiga boostada: 20-10-2022